About Us

Foundry pattern makers by trade, we offer an experienced supply of Sand Printed moulds and cores including file preparation and Casting simulation with reports, project management, casting and machining sourcing, all types of 3D printing in plastic and metal. See below.

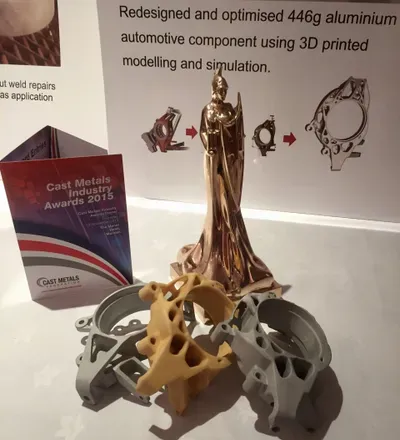

In 2015 we won the Cast metal federation, Best Casting Award for the casting you see on this page. This casting demonstrates that we can break away from all traditional foundry boundaries that exist, from part lines, draft, undercuts, to zero machining, consistent accuracy and permeability of moulds.

Allowing Topology software to remove material that does not function in the components stress analysis, further reduces weight to offer designers total freedom to create the next generation of cast components. This is the future!

Our mission

Independent Simulation solutions

DMT Ltd introduces an indépendant digital package for foundries wordwide.

Digital Manufacturing Technologies is all about, Digital.

Patternmakers by trade and 19 years experience in developing and supplying innovative 3D printing techniques for the foundry industry, DMT realises the power of a total digital approach to produce right first time castings while focussing on reducing cost and sustainability.

Professional simulation is where a smart successful casting begins. Not only to produce a sound casting first time, but to recognise when a design could be improved before metal is poured, making for a more sustainable process. Simulation and 3DP allows significant flexibility in our process, eliminating process variables and guaranteeing total cost reductions.

Using Novacast software, DMT offers stand alone, Secure and credulous independent simulations for your past and present components.

Contact info@dmtltd.co.uk for further info or call +44 7932855400